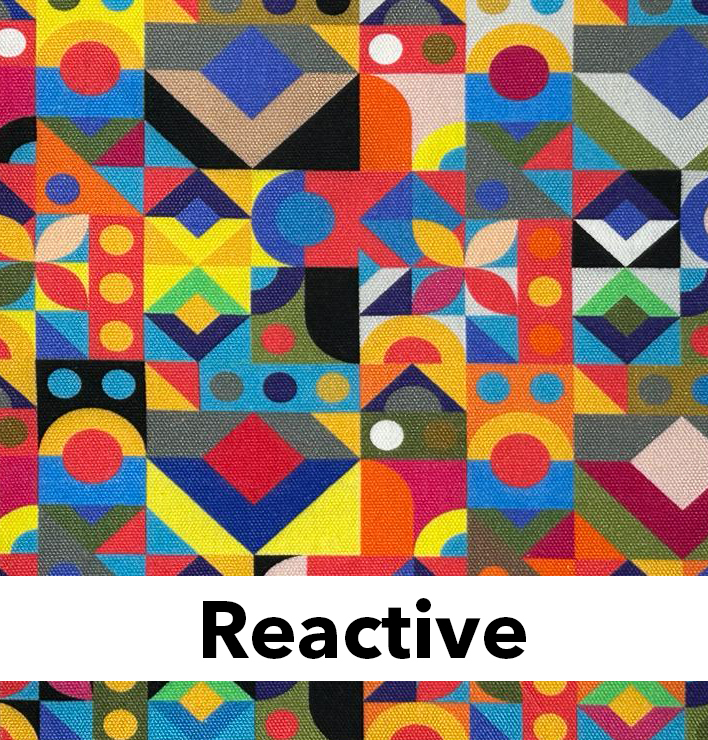

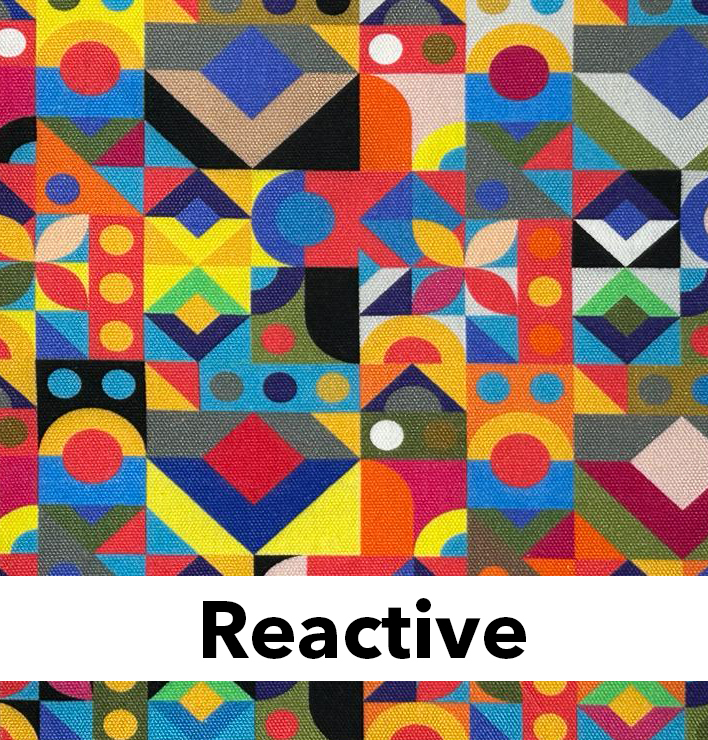

Printing with reactive dyes is used on cellulosic fabrics, such as cotton and viscose, (incl, EcoVero, Tencel and Lyocell) and other natural fabrics like silk. Reactive dyes require a dedicated steam fixation process to link the dye with the fibres of the fabric to preserve the color for long-lastingness. It also involves increased production costs and dedicated technology expertise, resource consumption and appropriate machinery. So not every digital fabric printing house offers reactive printing.

Using reactive dyes is still the best method of printing on cellulosic and natural fibres delivering the high-quality, long-lasting, sustainable prints which are resistant to washing, fading and cracking as desired for high-end fashion.

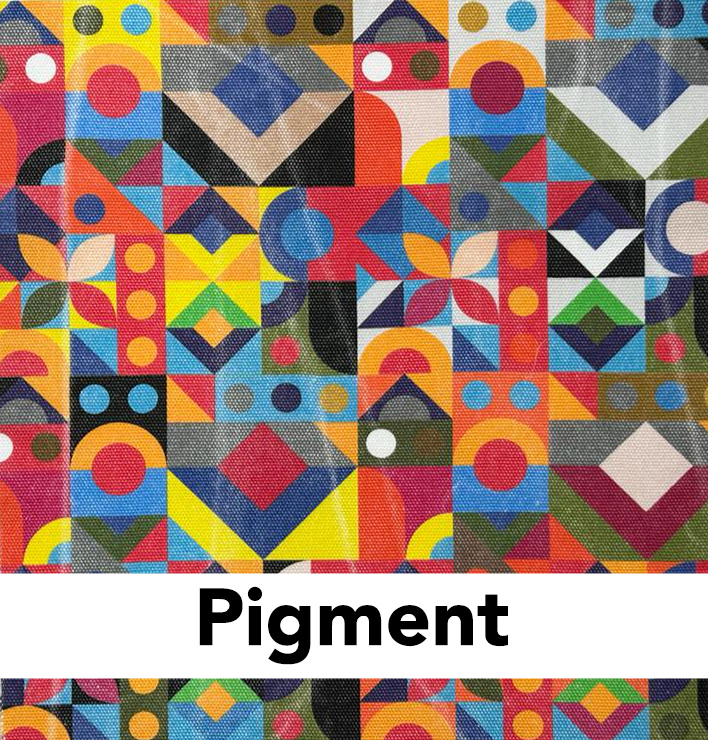

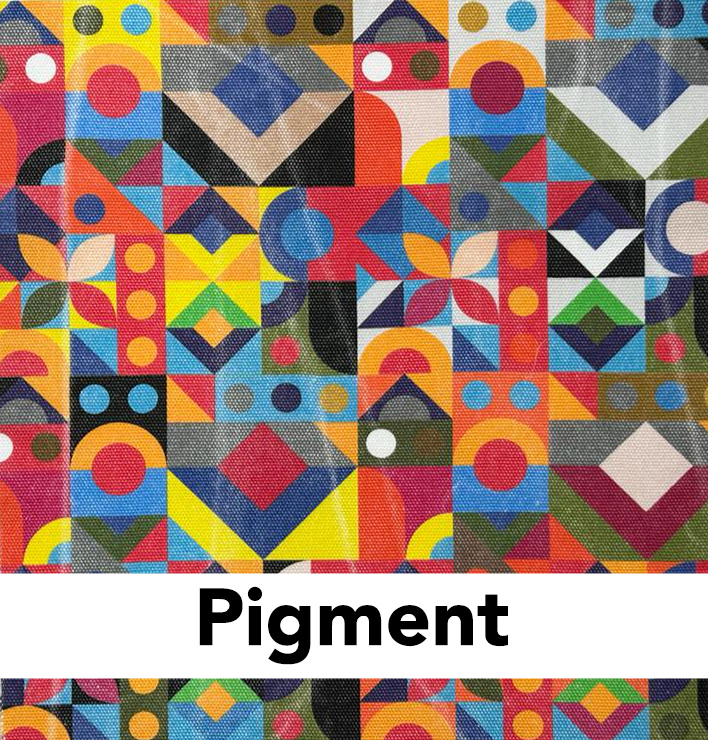

Reactive and Pigment printing are two of the five digital textile printing applications. Printing processes are divided according to the type of ink used. In this blog we will tell you all about it.